tsc offers a range of technical training courses. We can deliver any of these courses as live online sessions, tailoring them to your needs. Alternatively courses can be held in person at your premises.

We offer courses in the following areas of technology:

Remelt and Casthouse | Extrusion Process | Rolling Process | Product Metallurgy

Many aluminium plants struggle to employ qualified metallurgists. This is partly because many universities are no longer teaching metallurgy, and those that do treat it as a sub-set of materials science. And within that sub-set, precious little time, if any, is devoted to aluminium metallurgy.

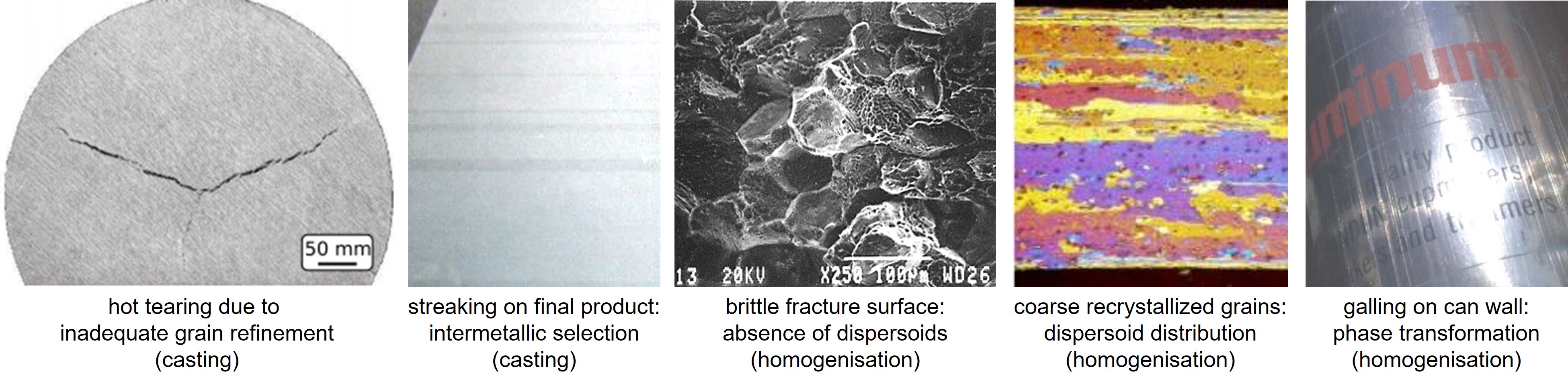

At tsc we firmly believe that technical staff involved in the production of wrought aluminium products need a good grounding in aluminium physical metallurgy. The microstructure of a wrought product evolves throughout the process stream, but the journey starts with solidification and homogenisation, which is the focus of this course.

The course is delivered in 10 weekly 2-hour live online sessions. Each session focusses on one seminar, and launches an associated workshop which attendees tackle in their own time before the subsequent live session.

The course will be followed later in the year by companion courses: Extrusion Process Metallurgy and Rolled Process Metallurgy

Since 2008, many hundreds of delegates from over 50 companies in the aluminium industry have attended tsc technical training courses, with their unique blend of lectures and workshops consistently receiving excellent reviews.

Please contact us if you require further information.